Boosting Herd Genetics: Artificial Insemination Brings Big Benefits to Small Beef Herds

Genetic progress can be slow in beef cattle, but artificial insemination (AI) is a tool to help producers reach their herd genetic goals faster. That is the number one reason Brendon Crane immediately took advantage of this technology when he established Crane Cattle Company in Lorne Valley, Prince Edward Island, in 1990. The farm focuses on producing and finishing top-quality Hereford calves with their 30-head cow herd.

“As a small producer I couldn’t afford to buy those top-quality bulls that really fit with what I was looking to improve in my herd,” Brendon says, adding that “to improve the genetic base of your herd and be competitive, not just within a specific breed but also in the market, you need a different genetic base coming into your herd all the time.”

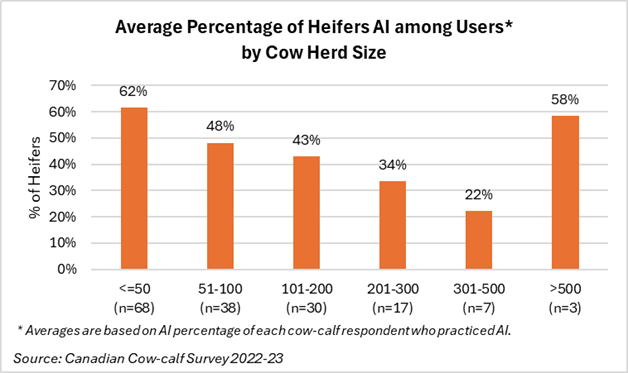

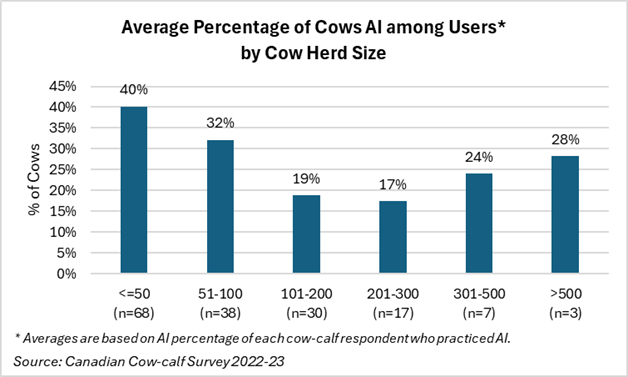

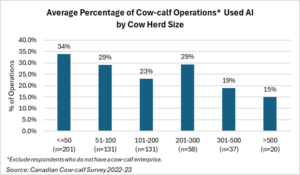

Although AI has been available for over six decades, it has not been widely adopted by Canadian beef producers. Results from the 2022-23 Canadian Cow-Calf Survey showed that 34% of producers with 50 cows or less used AI on their operations, with a trend for reduced usage with increasing herd size (Figure 1). Similarly, these small producers were more likely to AI a higher percentage of their heifers (62%; Figure 2) and cows (40%; Figure 3) compared to larger operations.

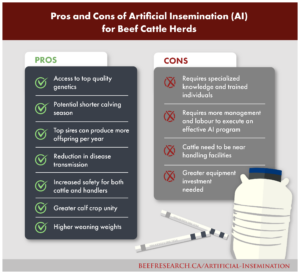

There are many benefits to using AI, including greater calf crop uniformity, reduced disease transmission, a shorter calving season with synchronization, reduced heifer injury, lower bull maintenance costs, increased handler safety and enabling top sires to produce more offspring per year than would be possible naturally.

Increased Access to Genetics Without Increased Bull Power

Genetic evaluation of beef bulls has improved considerably in recent years, making bull selection more objective and reliable. Moreover, sexed semen, expected progeny differences (EPDs) and the ability to select for specific traits identified through DNA markers now being available commercially increases the opportunities possible when using AI.

Will Stoneman, who owns and operates First Line Angus in Hagersville, Ontario, takes advantage of enhanced sire genetic predictability by bringing in semen from across Canada and the United States to create an animal balanced for both maternal and carcass traits. The 90-head operation consists of a purebred Angus herd, a purebred Simmental herd and a 40-head commercial herd. They also manage a small backgrounding program for their commercial calves.

“We sell a lot of bulls to commercial breeders who are finishing cattle as well, so they are looking for the carcass side of it,” Will explains. “In addition, AI allows us to not have the same number of bulls on farm, which is a huge win. With 90 cows, we would need to keep four to five mature bulls, which require additional facilities, management and labour.”

Like First Line Angus, AI has allowed Crane Cattle Company to increase genetic improvements within their herd by hand-selecting which cow families are bred to which bulls. This results in a consistent cow herd and calf crop.

“We focused on selecting sires to improve cow confirmation and temperament for a long time to develop a good, honest cow herd that works for our farm,” Brendon explains. “Now one of our goals is to breed more feed-efficient cattle. The cost of feed is always going up, so if you can reduce the amount of inputs, such as feed, the more profits you are going to have.”

Brendon reminds producers that “it may take two or more bulls and two to three generations to breed a specific trait out or in, so make sure you are choosing the right bull. And using AI gives you more flexibility to quickly change bulls to meet your goals.”

Timing of Insemination is Key to Success

The failure to detect estrous (heat) can be a costly problem with AI programs. Consequently, a successful program must begin with efficient and accurate heat detection.

Cows should be observed twice a day for 20-30 minutes at a time. Although the estrous cycle averages 21 days, it actually ranges from 18 to 24 days. Ovulation occurs approximately 24 hours after the beginning of standing heat. It has been shown that pregnancy rates can be improved when insemination occurs closer to the time of ovulation.

At Crane Cattle Company, all cows are bred with AI on the first breeding based on natural heats. Any cows that don’t conceive are turned out with a clean-up bull. Brendon has been an AI technician for more than 20 years and says the key to using natural heat is timing.

“Cows need to be bred 12-16 hours after standing heat. Many producers get anxious and breed too soon,” he explains.

The primary sign of heat is when a cow stands to allow a herd mate to mount. Secondary signs include attempting to mount other animals, chin resting, increased activity, clear mucous discharge from the vulva and swelling and redness of the vulva.

Breeding based on natural heats can be challenging. Amy Higgins, with Model Farm Angus in Quispamsis, New Brunswick, knows first-hand the impact of these challenges. She owns and operates the farm alongside her father Bob Higgins and focuses on producing purebred Black Angus bulls and replacement heifers for local purebred and commercial breeders.

“Cows need to be bred 12-16 hours after standing heat. Many producers get anxious and breed too soon.”

Brendon Crane, Lorne Valley, PEI

“Where we have run into issues with natural heats is when we don’t know how long she has been in heat. Did she start at midnight or 4 a.m.? In these cases, timing can be off which negatively impacts conception rates,” Amy explains.

She also emphasizes the need to house animals in groups to allow for the expression of clear signs of heat. “We had a group of heifers that were being custom fed off site. They were housed in a tie-stall barn, which limited typical estrous behaviours such as riding or increased movement,” she says, “and this resulted in poor conceptions rates.”

This year they are looking into purchasing ear tags to assist with heat detection. This technology works to monitor changes in animal behaviours which could indicate distress or heat. Data is collected and transmitted directly to a computer or mobile device. There are several other heat detection technologies available including pedometers, tail head markers and electronic devices that record mounting behaviour.

Amy suggests producers looking to breed with AI based on natural heats first determine the availability of an experienced AI technician in their area. “If access to a technician is limited, using a synch program may make more sense to ensure timely breeding,” she says.

Estrous Synchronization

Estrous synchronization protocols have virtually eliminated the need for heat detection in AI programs and enable the insemination of cattle when the operator desires; hence the name “fixed-time AI.”

The advantages of fixed-time AI include reduced labour due to no time spent detecting heat and insemination occurs at a pre-planned time, which can result in increased pregnancy rates. Synchronization protocols are generally divided into those that are estradiol-based and those that are GnRH-based.

MR RancHers, located west of Delisle, Saskatchewan, is owned and operated by Rachelle and Micheal Zoerb, along with their three daughters Tessa, Erica and Heidi. Their herd of 25 cows includes commercial Angus and Simmental cross cows along with a purebred Charolais herd.

The farm implemented an estrous synchronization program when they began using AI during the 2023 breeding season. That year they bred 10 of their top cows and experienced great success with an 80% conception rate. The following year, they bred 20 cows (both commercial and purebred) in two groups of 10, bred seven days apart.

“The first round of 10, we had 100% conception rate with two sets of twins, so we were actually 120%,” Rachelle explains. “We weren’t so lucky with the second set of 10 as a snowstorm hit that day, adding extra stress for the cows. Although we still ended up with 60%.”

Rachelle stresses that executing an effective fixed-time AI program takes commitment, and it is important to adhere to the synchronization protocol, hormone handling and administration.

“It costs money; it is an investment in your herd. So, when you look at it that way, it makes sense to do your due diligence to ensure each step in the process is being done in the right order and being done properly,” she says.

Focus on Pre- and Post-Breeding Management

Management of cows prior to insemination is crucial for increasing conception rates. Fertility in an AI program is a product of female fertility, semen fertility, inseminator skill and timing of AI. It is vitally important to realize that a deficiency in any one of these components, or sub-optimal performance in two or more, will substantially decrease pregnancy rate.

“We like to have our cows on 4-6 lbs of barley grain morning and evening as soon as calves start hitting the ground,” Erica, with MR RancHers, says. “We also provide free access to minerals and salt a minimum of 30 days before insemination. The key is to ensure their nutrition is optimal and they are in good body condition.”

Erica adds that they pay extra attention to the heifers. “You want to make sure they have enough nutrition to sustain their own growth plus the growing calf.”

This year, the cows selected for AI are housed in a dry lot separately from the remainder of the herd which allows for closer management of the feeding program and reduces any extra energy expenditure for the cows. Animals are also managed with a strict herd health program and dewormed a minimum of 14 days prior to breeding.

Rachelle emphasizes that it is also critical to minimize stress post-breeding. “Our cows stay at the home site for a minimum of 45 days after breeding, preferably 60 days before they are hauled to pasture. This extra time reduces the potential for them to slip that calf.”

Artificial Insemination Offers Flexibility to Meet Target Markets

Yearling bulls produced at Model Farm Angus are marketed through the Maritime Beef Testing Society Annual Breeding Stock sale which takes place the first Saturday of April. Requirements for this sale are for bulls to be born from December 1 to February 28, and each bull undergoes a series of reproductive performance tests.

To meet these requirements, they have recently started using sexed semen to increase the number of bull calves born in December. The cost for sexed semen can range from $20 to $60 in addition to the typical cost of $10 to $30 per semen straw.

“We aim for December-born bulls as they consistently pass the breeding evaluation tests prior to the sale,” Amy explains. “We’ve had bulls born in November, but we don’t really have a market for them because the test station won’t take them, and we don’t have the means of feeding them out. Similarly, bulls born in February are less developed and have more potential to fail the tests.”

Breeding programs and goals will look different for every beef producer. However, improvements in available technologies, such as sexed semen and estrous synchronization, increase the options available when implementing AI.

Top Tips for Successful Artificial Insemination

- Minimize stress pre- and post-insemination. “Use low-stress handling methods and be calm.” –Rachelle Zoerb, Delisle, SK

- Manage first-calf heifers appropriately. “First calf heifers are the hardest to get back in calf, so ensure you have enough energy in front of them to maintain condition.” — Will Stoneman, Hagersville, ON

- Record-keeping is key! “Success and continuous improvement come from documentation pre-, during and post-breeding.” — Rachelle Zoerb, Delisle, SK

- Hire an experienced AI technician. “A good technician has the experience to help make the process successful.” — Amy Higgins, Quispamsis, NB

- Know your operation’s breeding goals. “Depending on the company you are going with for selecting a bull, you may have a list of over 300 bulls, which can get overwhelming to sort through. Have your breeding goals in mind to help narrow down your search.” — Will Stoneman, Hagersville, ON

- Ensure a well-planned and implemented program. “Have a plan in place, follow protocol requirements and reduce animal stress.” — Rachelle Zoerb, MR RancHers, Delisle, SK

- Have the proper facilities in place to use AI. Not having the necessary equipment is just a “recipe to get hurt.” — Will Stoneman, Hagersville, ON

- Talk with your veterinarian and AI technician to develop a program that fits your farm. “Professionals can help set up a program that is right for your operation.” — Brendon Crane, Lorne Valley, PEI

Sharing or reprinting BCRC posts is welcome and encouraged. Please credit the Beef Cattle Research Council, provide the website address, www.BeefResearch.ca, and let us know you have chosen to share the article by emailing us at info@beefresearch.ca.

Your questions, comments and suggestions are welcome. Contact us directly or spark a public discussion by posting your thoughts below.