Injection Best Practices for Beef Cattle - New Resources ▶️

Practice Makes Perfect: Little Things Done Right Lead to Big Rewards

When a beef cattle producer chooses to give cattle injections, there is a series of decisions that can have a big impact on carcass quality at the end of the production line, as well as on the efficacy of the products being injected.

While it may seem innocent enough to ignore best practices when injecting an animal that is far from entering the food chain, these decisions impact the entire industry. Each sector will ultimately be more profitable if everyone works together to ensure a quality product.

Due to increased prevalence rates, injection site lesions (ISL) cost the Canadian beef industry $0.56/head or $1.63 million in 2016 compared to $0.21/head or $662,951 in 2011.

As shown in the BCRC’s new cattle injection resources, there are many steps that can be taken to reduce or eliminate ISLs and ensure the products being injected can work as intended. Following a few simple steps can have a big impact on the health and welfare of the animal being treated and keep dollars in the pocket of the producer.

Restraint

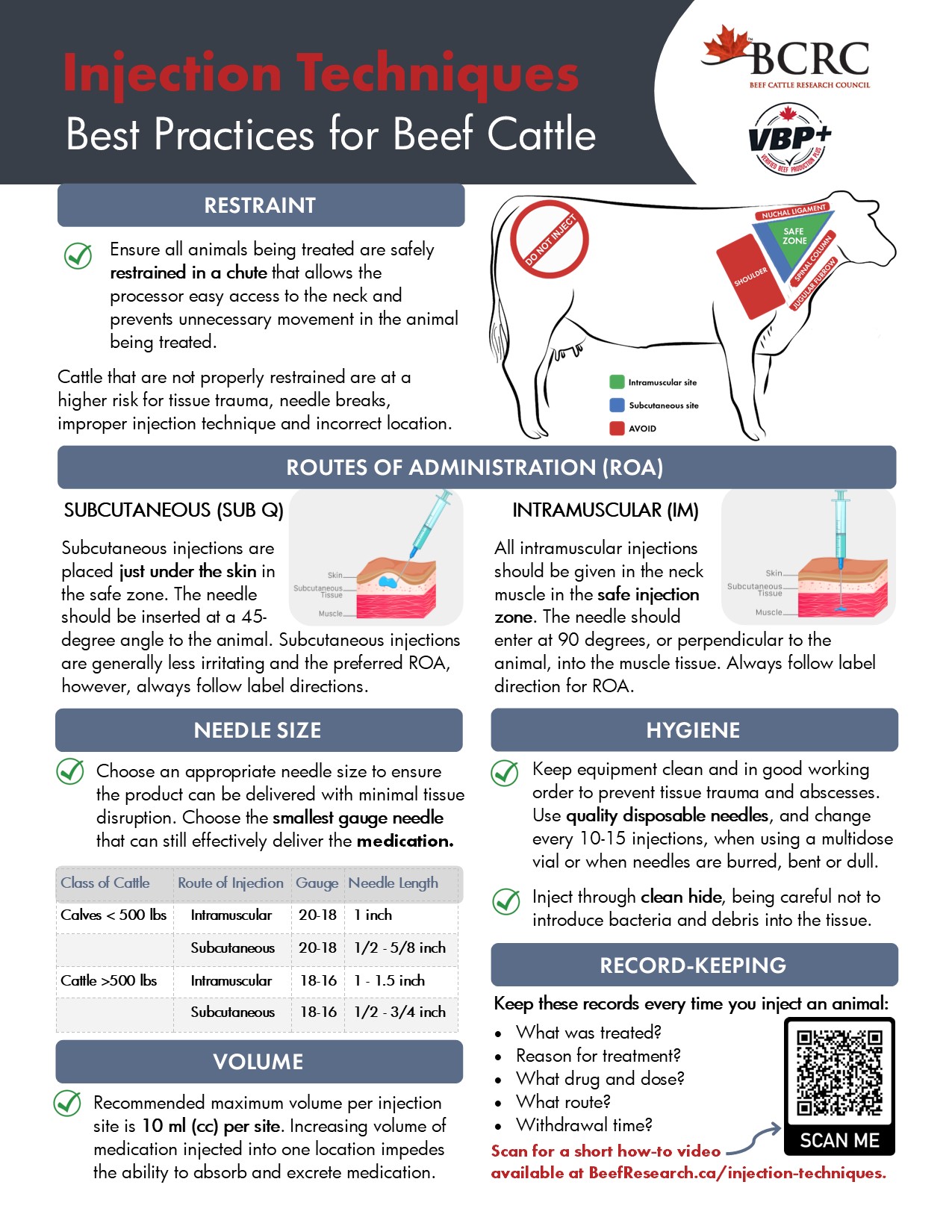

Ensure all animals being treated are safely restrained in a chute that allows the processor easy access to the neck and prevents unnecessary movement in the animal being treated. Cattle that are not properly restrained are at a higher risk for tissue trauma, needle breaks, improper injection technique and incorrect location.

Routes of Administration (ROA)

Subcutaneous (SubQ)

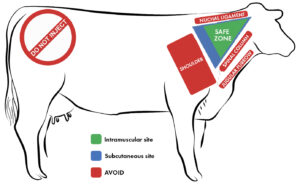

Subcutaneous injections are placed just under the skin in the safe zone. The needle should be inserted at a 45-degree angle to the animal. Subcutaneous injections are generally less irritating and the preferred ROA, however, always follow label directions.

INTRAMUSCULAR (IM)

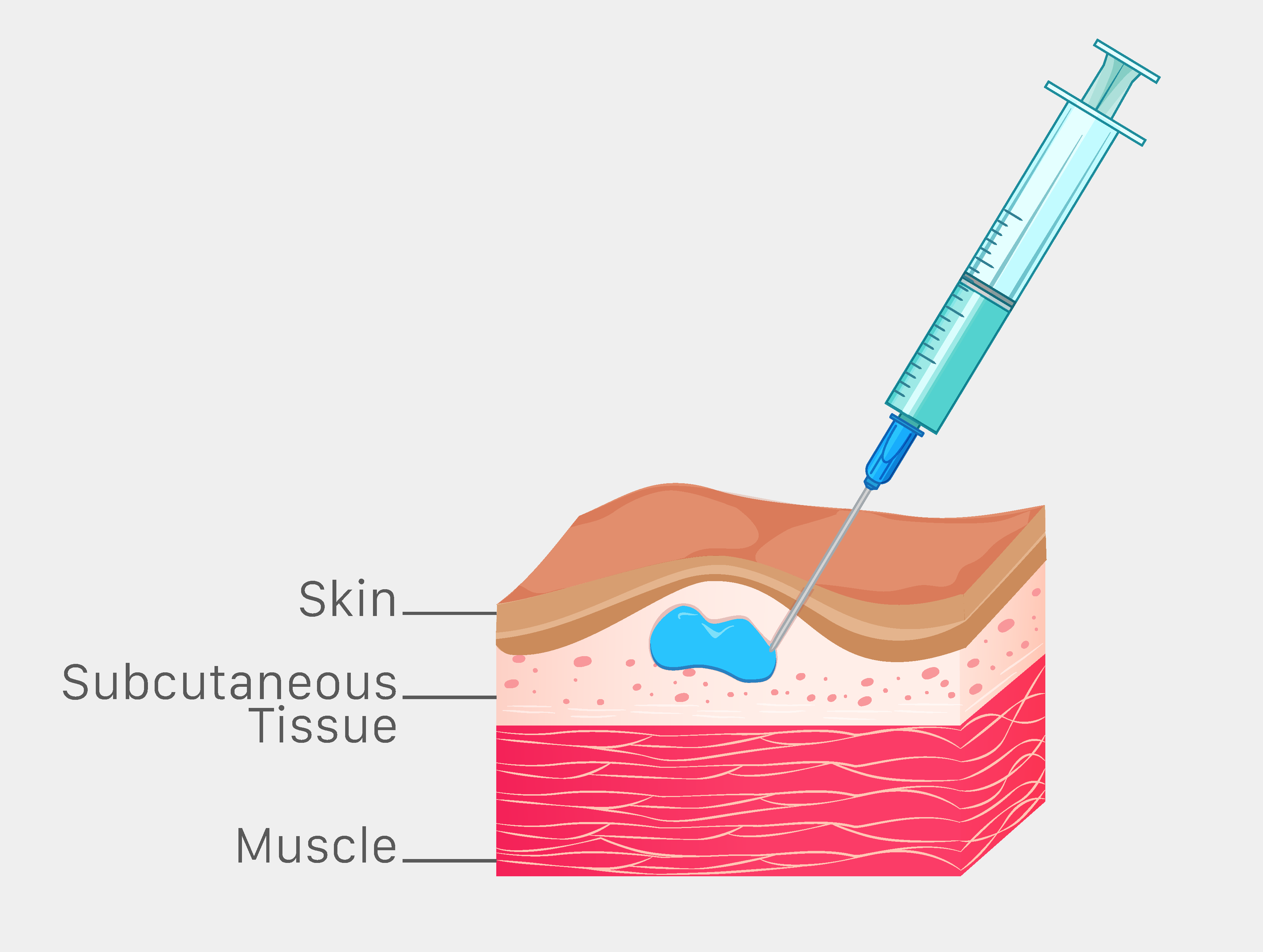

All intramuscular injections should be given in the neck muscle in the safe injection zone. The needle should enter at 90 degrees, or perpendicular to the animal, into the muscle tissue. Always follow label direction for ROA.

Needle Size

Choose an appropriate needle size to ensure the product can be delivered with minimal tissue disruption. Choose the smallest gauge needle that can still effectively deliver the medication.

| Class of Cattle | Route of Injection | Gauge | Needle Length |

|---|---|---|---|

| Calves < 500 lbs | Intramuscular | 20-18 | 1 inch |

| Subcutaneous | 20-18 | 1/2 – 5/8 inch | |

| Cattle >500 lbs | Intramuscular | 18-16 | 1 – 1.5 inch |

| Subcutaneous | 18-16 | 1/2 – 3/4 inch |

Volume Per Injection Site

Recommended maximum volume per injection site is 10 ml (cc) per site. Increasing volume of medication injected into one location impedes the ability to absorb and excrete medication.

Hygiene

- Keep equipment clean and in good working order to prevent tissue trauma and abscesses. Use quality disposable needles, and change every 10-15 injections, when using a multidose vial or when needles are burred, bent or dull.

- Inject through clean hide, being careful not to introduce bacteria and debris into the tissue.

Record-Keeping

Keep these records every time you inject an animal:

- What was treated?

- Reason for treatment?

- What drug and dose?

- What route?

- Withdrawal time?

ADDITIONAL RESOURCES:

- The Five W’s of Beef Cattle Injections: Who, What, When, Where & Why (BCRC post)

- Remote Drug Delivery (BCRC topic page)

- Remote Drug Delivery Devices – What You Need to Know (BCRC post & video)

- Vaccine Handling Tips (PDF)

Sharing or reprinting BCRC posts is welcome and encouraged. Please credit the Beef Cattle Research Council, provide the website address, www.BeefResearch.ca, and let us know you have chosen to share the article by emailing us at info@beefresearch.ca.

Your questions, comments and suggestions are welcome. Contact us directly or spark a public discussion by posting your thoughts below.